Barium tungsten cathode

Barium tungsten cathode

Preservation and operation of electrodes

The reserved barium tungsten cathode is composed of porous matrix and evenly filled barium salt.

In order to ensure the effectiveness of barium tungsten cathode products, it is required not to be exposed to the atmosphere for more than 48 hours before use. It is required to prevent moisture, dust and other pollutants from contacting the products to the greatest extent. In order to ensure the best performance, it is better to store the electrode in the condition of less than 0.1Pa or in dry inert gas (dry nitrogen or argon). When the electrode absorbs too much moisture, spots may appear on the surface of the product during the heating process before subsequent use, which can be reduced or prevented by reducing the heating speed.

All manipulation of the electrodes should be carried out in a very clean and dry environment. Grease or other contamination on the fingers will affect the activation of the electrodes and the performance of the finished lamp.

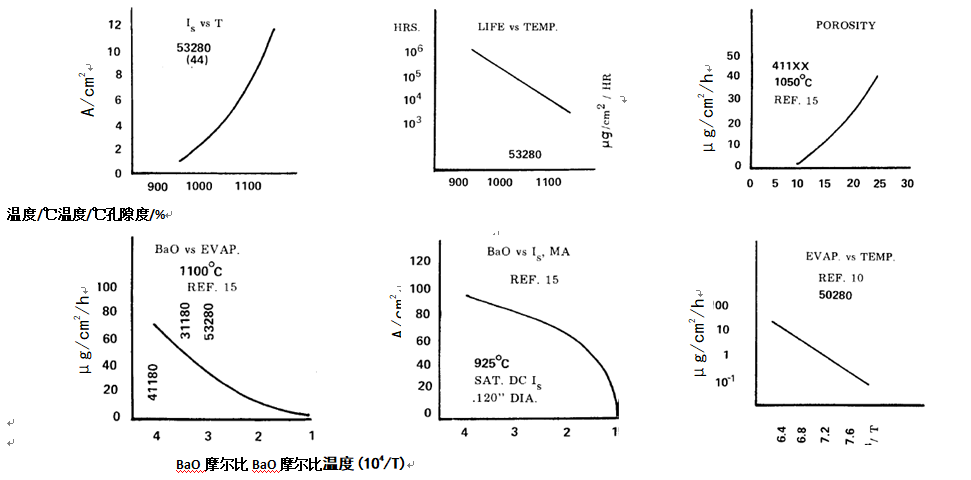

Barium tungsten cathode has a wide operating temperature. When used at high temperature, the emission current of the electrode is large, but its service life is short. When used at low temperature, the emission current is small, but its service life is long.

Electrode activation

According to the following process generally barium tungsten cathode can be fully activated, but because of the way of heating equipment, temperature measuring equipment companies, vacuum system are different, the following conditions are for reference only, before activating the best calibration temperature measuring system, after many experiments to determine the better activation temperature and time, as far as possible to improve the system of vacuum degree in the process of the lamp.

Temperature, time and vacuum need to be adjusted according to the size of the electrode or lamp, a large lamp or electrode needs higher temperature, longer time and higher vacuum.

Better performance and more stable quality can be achieved by activating the electrode and maintaining a lower vacuum degree in the process of lamp installation.

The activation process can be divided into two steps. The first step is to remove impurities and oxides from the electrode. The second step is the activation of salt, which needs to be completed by diffusion in the environment of high temperature, long time and high vacuum. Both steps are very important. When there is residual water vapor in the lamp tube, the tungsten matrix will react with H2O to generate WO3, which will deposit on the glass inner wall in the form of black spots.

1) and the electrode of tube heated to 700-850 ℃, heating and vacuum should be continued, this process is to remove the moisture in the electrodes and tubes and other miscellaneous gas, when the vacuum degree is no longer falling and is less than 10-5 pa, begin the activation of step 2;

2) slowly raise the temperature to 1200 ℃ and keep 1 to 2 h, in the process of the vacuum degree should be only a slight rise, if vacuum degree rise is bigger, may be is caused by volatilization of barium salt, need appropriate to reduce the temperature, the activation step faster is complete, the pressure inside the tubes should be between 10-6-10-7 pa, it has been fully activated cathode.

3) the electrodes can be activated one by one in the process of lamp installation, or they can be uniformly activated by installing multiple electrodes in quartz tubes in a planned way before use. After the activation is completed, argon is injected into the equal-tube, which will be used immediately after being stored for a short time.